Gas Saving Expansion Tank (GSET)

A client requested a catch tank for overflow. His concept was to trap the overflow in a catch tank, which would siphon back into the auxiliary tank when it drained. Recovering this previously lost gasoline could yield as much as $1.00 per fillup. For a long distance rider this could quickly pay for the system.

He had a great idea and we have incorporated into our product line as the Gas Saving Expansion Tank (GSET).

Overflow Operation:

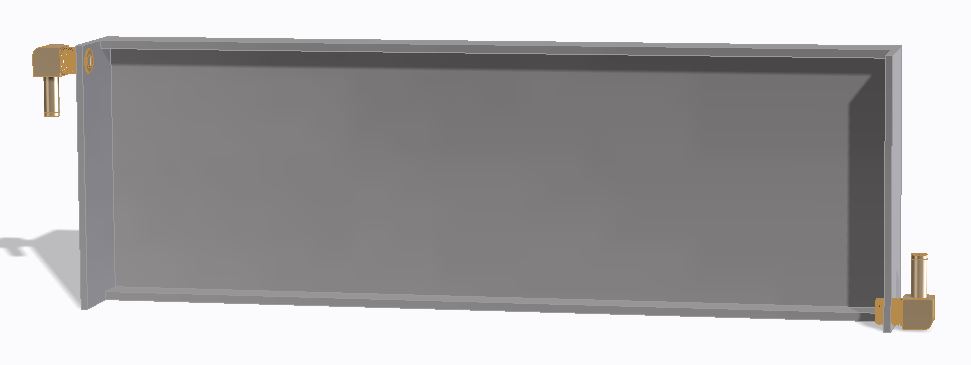

The inlet of the GSET is a 1/4" hose barb fitting placed at the BOTTOM of the tank. As the fuel expands in the main tank it flows into the overflow tank. This overflow tank is engineered to hold most, if not all, of the expansion expected from the auxiliary tank (see GSET Tank Sizing below).

Vent Operation:

The outlet of the GSET is a 1/4" hose barb fitting placed at the TOP of the overflow tank. When the auxiliary tank drains, a vacuum is created at the overflow fitting causing a low pressure in the catch tank, the low pressure is offset by outside air entering the tank via the vent line. Fuel in the catch tank is siphoned back into the auxiliary tank.

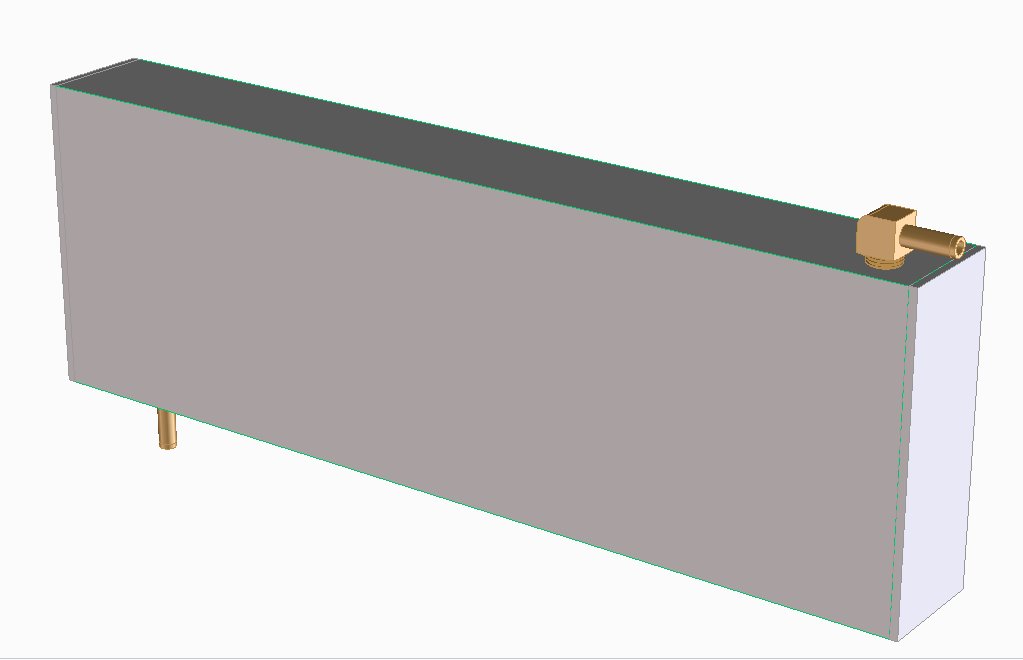

We are building these out of 6061 extruded aluminum tubing with end caps welded in place. The GSET is pressure tested to verify no leakage.

Currently, two base sizes are available 1-1/2" x 4" and 2" x 3". We can make these any length required to meet your expansion tank size needs.

The GSET is mounted to any convenient location using Very High Bond, High Temp rated 3M Dual Lock. We include a Velcro security strap in the unlikely event that you would hit a chuckhole with enough force to dislodge the Dual Lock.

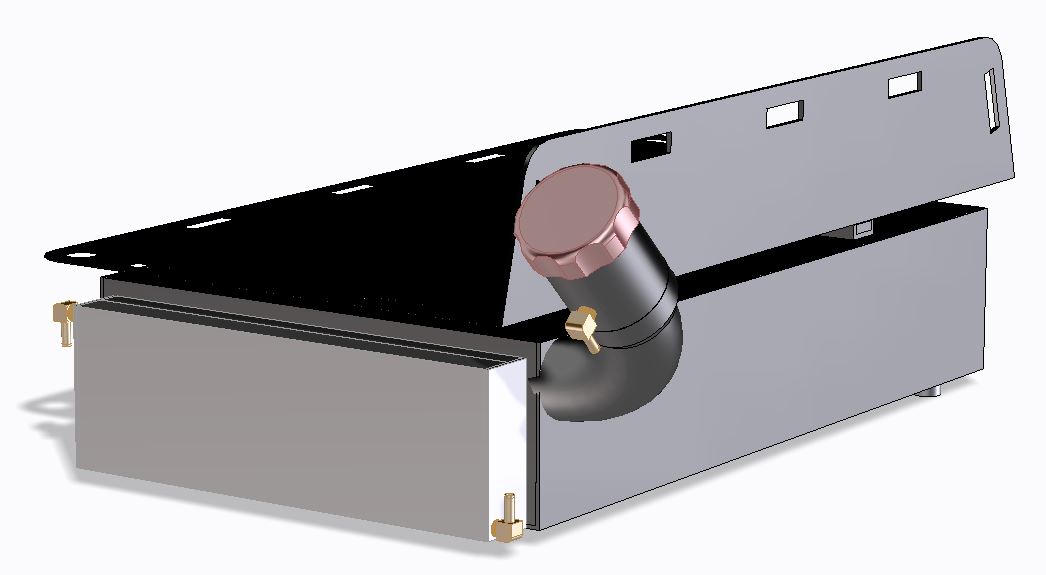

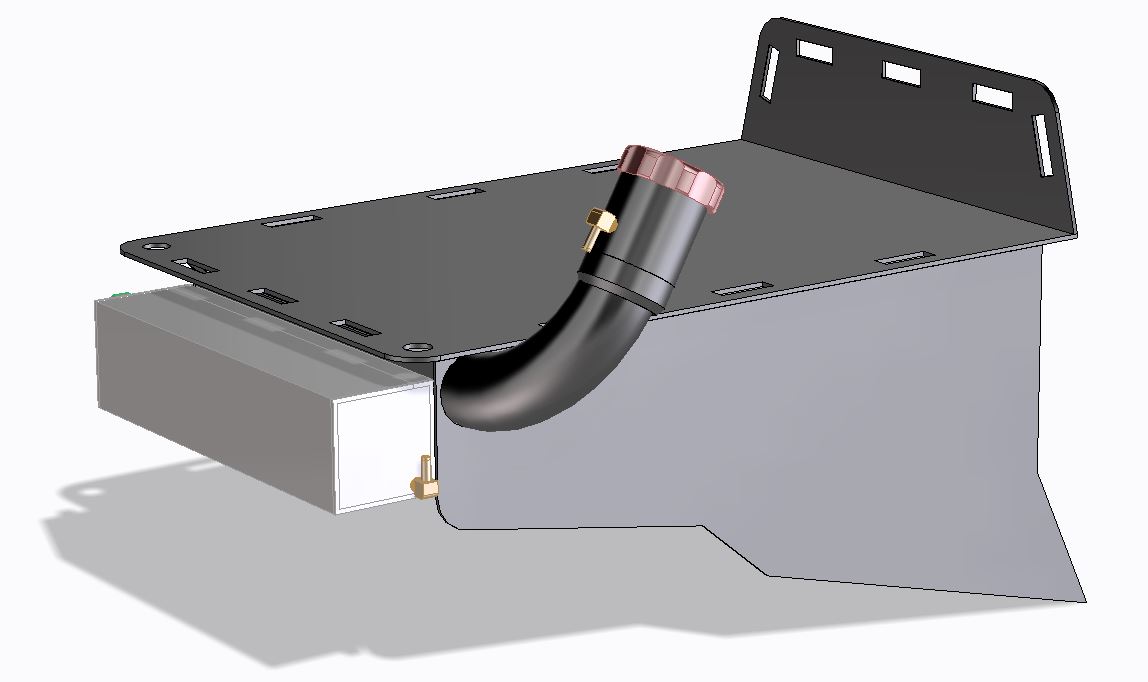

Here is how the 1-1/2" x 4" GSET would be mounted on an LRM system:

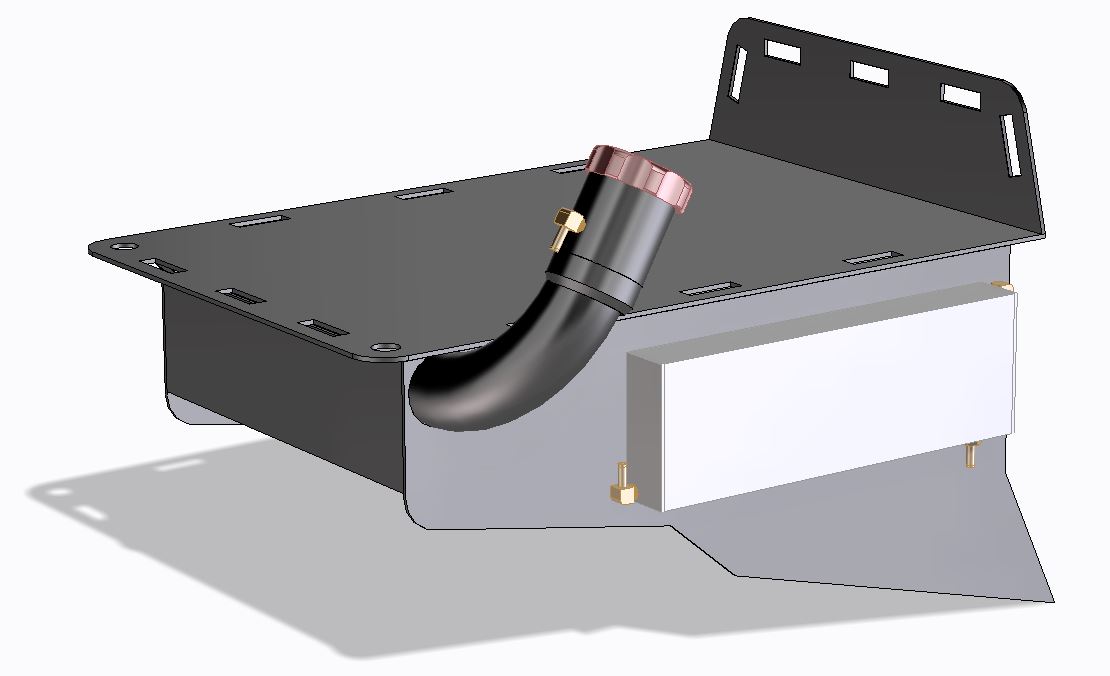

An FJR could mount a 1-1/2" x 4" GSET on the side

or a 2" x 3" GSET on the rear:

Price is $50 and includes the hardware and plumbing needed for installation. Powder coating is extra unless the GSET is included with a tank order.

This email address is being protected from spambots. You need JavaScript enabled to view it.us to order.

https://maplefarkles.com/~maplef5/index.php/products/gset#sigProIdb1eb8295df

- Would the capacity of the GSET count during a technical inspection for tank capacity?

Good question. We've asked and the official answer was; "The volume of the expansion tank will not count as long as two conditions are met: 1) it is filled by a vent line high in the filler neck, 2) the size of the venting hole is 1/8" or less." Our vent fitting is above the tech inspection fill line and the vent line is restricted to 3/32". - What happens during a tipover?

If the bike were tipped over, fuel would first flow into the vent tank, once the vent tank was filled, fuel would then be vented to the atmosphere. The worse case is that the system acts like a normal vent tube, but slower due to more piping restriction. and when it filled to the overflow tube, begin slowly leaking it out the overflow tube. In some cases, we might even get a vapor lock and experience no leakage. An anti tip-over valve could be fitted to the vent outlet port with no impact on performance. - Do you recommend this?

I have one on my bike. I like it because it keeps gas from spilling on the road (environmentally sound) and it keeps me from paying for that gas on the ground. I do think it will pay for itself eventually, theoretically you'll save about 1/2 liter of gas or more each fill up. - Does it cause transfer problems?

On rare occasions it has refused to start a siphon (maybe once in 10-15 fill ups). Here's how I use my aux. I wait for the low fuel light to come on, open the valve to the tank, and then watch to see that the low fuel light goes out indicating that I have good transfer. The reason I watch the low fuel light is that the gas gauge is very slow to change whereas the light is more responsive. I can fill up in a station and go a mile or more down the road before my gas gauge shows full. On those rare that my low fuel light hasn't gone out in a while, I reach back and loosen the cap on the aux tank to start fuel flow. Less than a minute later I tighten it back down. So far, has worked every time.

In a nutshell we need an expansion tank which is 5% of the capacity of the auxiliary tank. As long as we are equal to or greater we should never spill any gasoline.

Here is the math behind the volume calculations for different tank sizes:

Gasoline generally expands about 0.0005278 in3/in3/°F

Overflow from a full tank is therefore:

- VolumeSpilled = GasVolume * 0.0005278 * (ChangeInGasolineTemperature )

To figure GSET size, we estimate the maximum temperature change. Let's say pumped gasoline is 60°F in summer and gets to 140° sitting in the sun. (Change = 80°F).

- CatchTankSize = GasVolume * (0.0005278) * (80) = 0.042224

To provide some extra space, so sloshing in the GSET doesn't spill overboard, we add a Factor of Safety of 25% (1.25 * 0.042224 = 0.05278).

We can safely round this down since the aluminum tank will expand as well [The volumetric expansion for Aluminum is about 0.0000369 in3/in3 per °F]

This tells us that the GSET should be about 5% of the auxiliary tank volume.